Pressure Reducing Valve/Drain Separator

Questions

- Q Should we insulate pressure reducing valves for steam?

- Q In selection of pressure reducing valve, is it necessary to consider safety factor?

- Q We repeatedly face troubles on a pressure reducing valve only on the same location of the steam system, but those on other lines are satisfactory. What is the possible cause?

- Q What is the recommended mesh size of the strainer installed before the pressure reducing valve?

- Q What will happen if a flow rate higher than pressure reducing valve's capacity is given?

- Q Do you have pressure reducing valves with rust-resitant material?

- Q Which pressure reducing valves should we select for water?

- Q What is the advantage of using pressure reducing valves for steam?

- Q Many of Yoshitake's pressure reducing valves are made of ductile cast iron (FCD450). What is the difference from gray cast iron (FC200)?

- Q Are current models compatible with old models?

- Q What is precaution for using a pressure reducing valve for steam?

- Q How should we select pressure reducing valves for steam?

- Q What is the advantage of an external sensing type?

- Q Please explain "reduction ratio" and "rangeability".

- Q How should we adjust pressure reducing valves?

- Q Outlet pressure of a pressure reducing valve at work drops when the flow rate increases. Is this malfunction?

- Q What is the possible cause of outlet pressure drop?

- Q What problem will occur if the flow rate decreases to lower than the minimum adjustable flow rate?

- Q Is it possible to supply pressure reducing valves factory-set?

- Q Some pressure reducing valves are mentioned to be installable horizontally and vertically. Can they be installed in any posture?

- Q Can the screen of GD-55/56 be replaced?

- Q Can GD-55/56 be set at pressure other than 80kPa?

- Q Can pressure reducing valves control flow rate?

- Q What are venefits of installing a bypass valve?

- Q What is the service life?

- Q How often the valve should be inspected regularly?

- Q What should we do before suspending operation of a steam pressure reducing valve for a long time?

- Q Can a pressure reducing valve and a strainer be connected directly?

- Q Are pressure reducing valves factory-set when shipped?

- Q Should we install a strainer on the inlet side of a pressure reducing valve for water?

- Q If we conduct airtight test after piping construction, what is the allowable maximum pressure pressure reducing valve?

- Q Do you have dedicated insulation material for GD-46 series pressure reducing valve for individual water supply?

- Q Will the outlet pressure change if the inlet pressure changes?

- Q Is it OK to use pressure reducing valves with pressure gauges attached?

- Q Can pressure reducing valves installed outdoors?

- Q Can pressure reducing valves used in parallel?

- Q What is the difference between A type and D type of the pressure gauges used on pressure reducing valves for water and air?

- Q Can pressure reducing valves for steam be used on pipes in a direction other than horizontal?

- Q Can GP-2000 series be used without the outlet pressure sensing pipe?

- Q Do you have pressure reducing valves compliant with regulations of China?

- Q What should we pay attention to when selecting pressure reducing valves?

- Q Is the adjusting spring of pressure reducing valve replaceable?

- Q What is the range of length of the outlet pressure sensing pipe of GP-2000?

- Q What should we do if the pressure reduction ratio is over 20:1?

- Q Is there any precaution on the installation positions of a water pressure reducing valve (example: GD-55) and a relief valve (example: AL-52) for home boiler?

- Q What is the flow velocity with which drain separator works effectively?

QShould we insulate pressure reducing valves for steam?

Yes, in terms of reducing energy loss by heat release. We offer Y's jacket, easily detachable insulation cover for each of our model.

QIn selection of pressure reducing valve, is it necessary to consider safety factor?

Yes. Please allow a safety factor of 10 - 20 %.

QWe repeatedly face troubles on a pressure reducing valve only on the same location of the steam system, but those on other lines are satisfactory. What is the possible cause?

There may be influence of foreign substance or condensate in piping. Installation of drain separator is recommended.

QWhat is the recommended mesh size of the strainer installed before the pressure reducing valve?

80 to 100 mesh is recommended.

QWhat will happen if a flow rate higher than pressure reducing valve's capacity is given?

The valve can face problems such as vibration or rapid drop of outlet pressure. Selecting pressure reducing valves with small offset and large Cv value, for example GP-2000, may provide better performance.

QDo you have pressure reducing valves with rust-resitant material?

We offer models with wetted parts stainless steel such as GP-1000SS and GD-41, or all-stainless models such as GP-1000AS and GD-20.

QWhich pressure reducing valves should we select for water?

The valve can be selected according to the flowrate and the pressure. Yoshitake also offers choices of materials, such as ductile cast iron, bronze and stainles steel. For drinking water, follow the local laws and regulations.

QWhat is the advantage of using pressure reducing valves for steam?

When using steam as heat source, latent heat can be used more effectively at low pressure, which contributes to energy saving.

QMany of Yoshitake's pressure reducing valves are made of ductile cast iron (FCD450). What is the difference from gray cast iron (FC200)?

FCD450 is safer than FC200 because it has higher mechanical strenght such as tensile strength. Yoshitake's integrated production system has enabled to control the cost and to use ductile cast iron as standard material.

QAre current models compatible with old models?

Some models have sucessors or spacer kits available. Please contact us for details.

QWhat is precaution for using a pressure reducing valve for steam?

If pressure is reduced, fluid velocity rises in piping of the same nominal size. It is necessary to take measures such as enlarging piping nominal size.

QHow should we select pressure reducing valves for steam?

The valve should be selected considering inlet pressure, outlet pressure and flow rate. Required Cv value can be calculated from these factors. Model GP-2000 is recommended for regulation at low pressure. However, attention has to be paid because selecting too large a valve will have disadvantages.

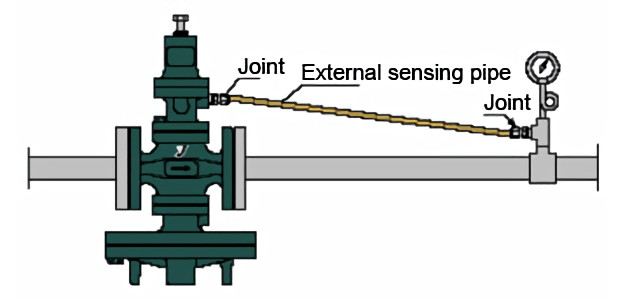

QWhat is the advantage of an external sensing type?

Using the external sensing type of valve gives many advantages, such as:

-Stable pressure control can be achieved even in the lines with the wide fluctuation in flow rate.

-Stable pressure control can be achieved since the pressure can be detected at the exact point where the pressure control is required.

-The pressure drop due to piping from the pressure reducing valve to the controlled point can be ignored.

GP-2000 features the external sensing function as its standard.

GP-2000 type pressure reducing valve (external detection)

GP-2000 type pressure reducing valve (external detection)

QPlease explain "reduction ratio" and "rangeability".

Reduction ratio is the ratio between inlet and outlet pressure of the valve. Generally it is expressed by the maximum ratio such as 10:1 or 20:1, etc. For example, if the inlet pressure is 2.0MPa and the outlet pressure is 0.1MPa, the pressure reduction ratio is 20:1. The rangeability is the ratio between rated flow and the minimum adjustable flow rate. The higher range ability means the wider control range of the flow rate, and it represents the high controllability of the valve.

QHow should we adjust pressure reducing valves?

QOutlet pressure of a pressure reducing valve at work drops when the flow rate increases. Is this malfunction?

Each pressure reducing valve has a characteristic called offset. Please refer to the catalog of each model.

QWhat is the possible cause of outlet pressure drop?

A strainer on the inlet pipe (or a built-in strainer of the pressure reducing valve) might be clogged. Fluctuation of inlet pressure can also be the cause.

QWhat problem will occur if the flow rate decreases to lower than the minimum adjustable flow rate?

Because of the structure of pressure reducing valves, valve opening will be unstable and the outlet pressure cannot be controlled normally.

QIs it possible to supply pressure reducing valves factory-set?

Yes. Please specify the set pressure at the time of ordering.

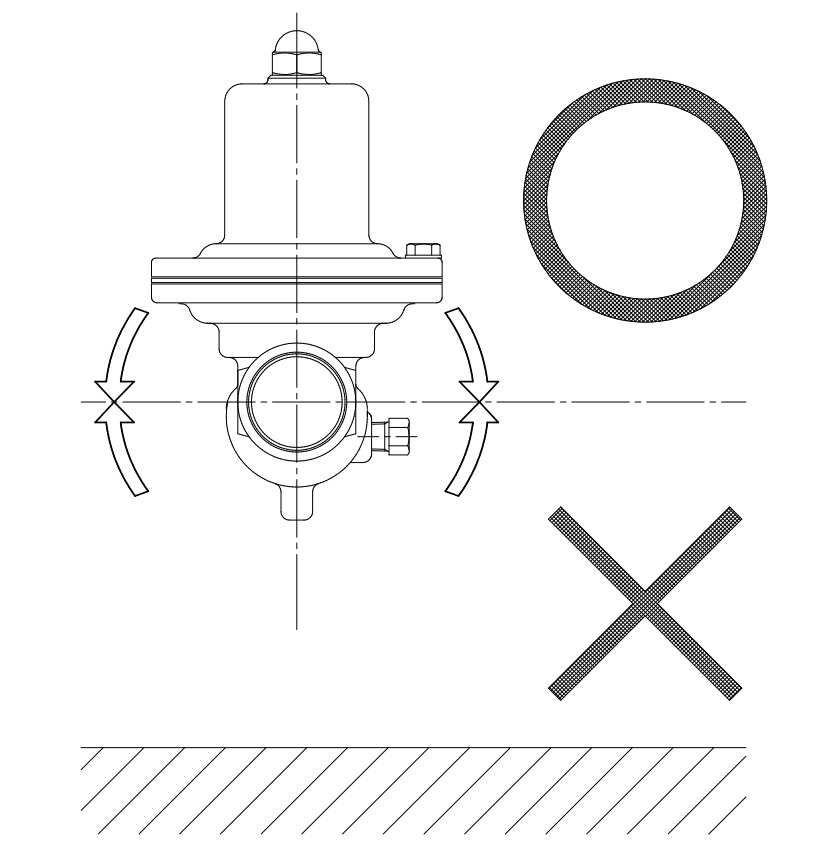

QSome pressure reducing valves are mentioned to be installable horizontally and vertically. Can they be installed in any posture?

Some models can be installed both on horizontal and vertical pipes, but they should be installed upright to sideways and cannot be installed upside down.

Installation position

Installation position

QCan the screen of GD-55/56 be replaced?

Yes. Please contact us for details.

QCan GD-55/56 be set at pressure other than 80kPa?

Yes. Please contact us for details.

QCan pressure reducing valves control flow rate?

Pressure reducing valves control outlet pressure and cannot control flow rate.

QWhat are venefits of installing a bypass valve?

A bypass valve can be used for flushing at the initial operation of the piping, draining steam condensate. It is also possible to service the pressure reducing valve while keeping the water flow.

QWhat is the service life?

It depends on working conditions and environments.

QHow often the valve should be inspected regularly?

Annual inspection is recommended.

QWhat should we do before suspending operation of a steam pressure reducing valve for a long time?

Drain condensate from the steam pipe as much as possible. After long suspension, please check the valve before assuming operation.

QCan a pressure reducing valve and a strainer be connected directly?

No problem, but it is recommended to add a short pipe between them for easy maintenance.

QAre pressure reducing valves factory-set when shipped?

They are set at our standard set pressure. (example: standard set pressure of GP-1000 is 0.1MPa.)

QShould we install a strainer on the inlet side of a pressure reducing valve for water?

Please install a strainer on the inlet side if the pressure reducing valve does not have a built-in strainer.

QIf we conduct airtight test after piping construction, what is the allowable maximum pressure pressure reducing valve?

Please keep the test pressure on the inlet side at 1.5 times of the working pressure or lower, and the test pressure on the outlet side at 1.2 times of set pressure of the pressure reducing valve or lower.

QDo you have dedicated insulation material for GD-46 series pressure reducing valve for individual water supply?

Please use the package material (expanded polystyrene) as insulation material.

QWill the outlet pressure change if the inlet pressure changes?

Yes, please refer to the pressure characteristics chart.

QIs it OK to use pressure reducing valves with pressure gauges attached?

For GD-46 and GD-25 series pressure reducing valves for individual water supply, please detach the pressure gauge after finishing pressure adjustment. Other pressure reducing valves can be used with a gauge attached.

QCan pressure reducing valves installed outdoors?

Yes, but not in freezing condition.

QCan pressure reducing valves used in parallel?

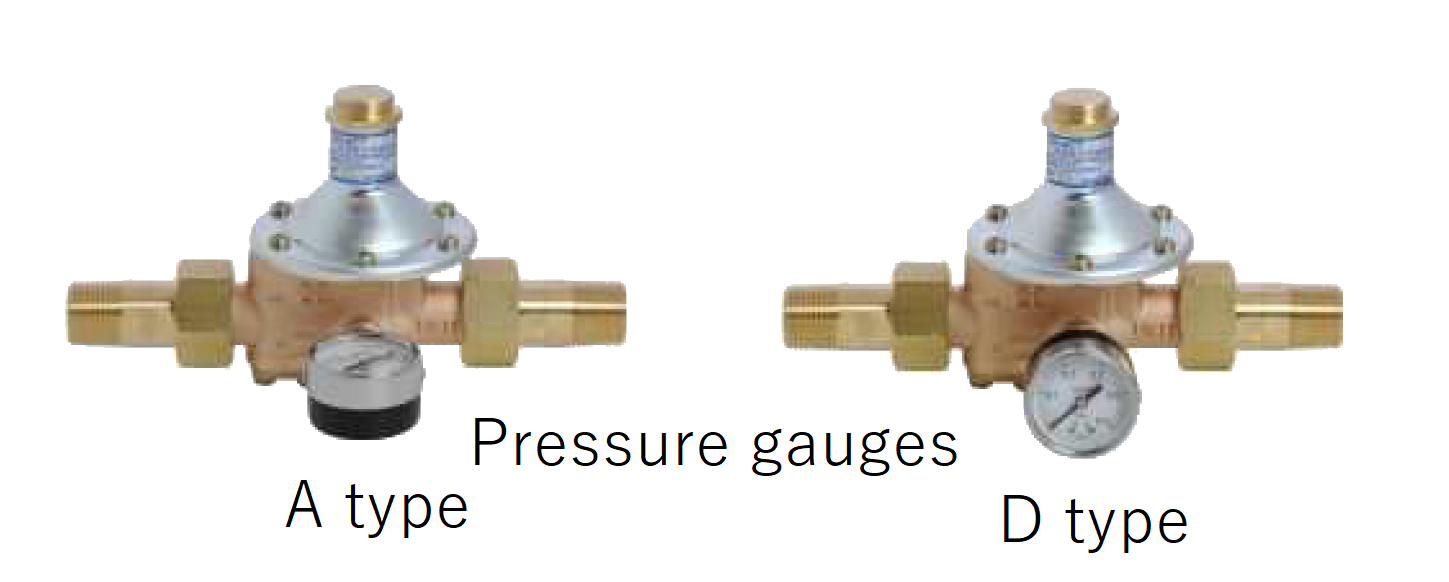

QWhat is the difference between A type and D type of the pressure gauges used on pressure reducing valves for water and air?

Please refer to the pictures.

A type and D type of the pressure gauges

A type and D type of the pressure gauges

QCan pressure reducing valves for steam be used on pipes in a direction other than horizontal?

No, they have to be used on horizontal piping.

QCan GP-2000 series be used without the outlet pressure sensing pipe?

No, they cannot. Internal sensing type is available as an option. Please contact us for details.

QDo you have pressure reducing valves compliant with regulations of China?

GP-1000 and GP-2000 are certified with the Pressure Piping Components Manufacture Appraisal Regulation.

QWhat should we pay attention to when selecting pressure reducing valves?

We recommend using a pressure reducing valve at 20 to 80% of its rated flow rate.

QIs the adjusting spring of pressure reducing valve replaceable?

Replaceable except for some models. Please refer to the manuals.

QWhat is the range of length of the outlet pressure sensing pipe of GP-2000?

0.5 to 5m, but 2m or shorter is recommended. Please install it in a downward slope.

QWhat should we do if the pressure reduction ratio is over 20:1?

Please install 2 pressure reducing valves to make two-stage reduction. The distance between them should be 3m or more.

QIs there any precaution on the installation positions of a water pressure reducing valve (example: GD-55) and a relief valve (example: AL-52) for home boiler?

Please install the pressure reducing valve at a location lower than the relief valve.

QWhat is the flow velocity with which drain separator works effectively?

Please use the separator with flow velocity 30m/sec or less for steam and 15m/sec for air.