Solenoid Valve/Motor Valve

คำถามที่พบบ่อย

- Q Can thermal insulation cover be put on a solenoid valve?

- Q What is the power consumption of the coil of the solenoid valve?

- Q How much water droplet can DP-100 solenoid valve endure?

- Q When the power is cut off while being energized, in which state does a motor valve becomes?

- Q When the power is cut off while being energized, in which state does a solenoid valve ?

- Q Abnormal sound can be heard from the coil of a solenoid valve while being energized. Is it a problem?

- Q How long is the service life of a solenoid valve?

- Q Can a throttle valve be used at the inlet side of solenoid valves?

- Q Can a solenoid valve be used with a three phase power supply?

- Q Can a solenoid valve be used at a place with explosive gas?

- Q The coil gets hot when solenoid valve is energized. Is it normal?

- Q Is it possible to use a solenoid valve outdoors?

- Q What is allowable ambient temperature when using a solenoid valve?

- Q Can solenoid valves be used for viscous fluids?

- Q What is the difference between pilot type and direct acting type of solenoid valves?

- Q Although the connection part of DP-100 series is made of stainless steel, is there any problem about galvanic corrosion with a steel pipe? In addition, is there any problem to exchange the solenoid valve made of bronze (DP-10) in use to the one made of stainless steel (DP-100)?

- Q Can a solenoid valve be installed to a place where the piping may be frozen?

- Q Are there any instructions on installation posture of solenoid valves?

- Q What kind of problem is expected when the outlet pressure of a solenoid valve exceeds the inlet pressure?

- Q Which size of mesh is recommended for the strainer before solenoid valve for steam to prevent foreign substances?

- Q When installing an ON-OFF valve such as a solenoid valve or a motor valve around the pressure reducing valve, in what distance should they be away from the pressure reducing valve?

- Q What is the maximum allowable temperature of the coil?

- Q Can a solenoid valve be used as an emergency shutdown valve?

- Q Are terminal boxes for solenoid valves available?

- Q Can the coils for 100/200V be used with 110/220V power?

- Q What kind of safety devices should be used?

- Q Can terminal boxes with lamp for rated voltage 100V be used with 110V?

- Q Is there any solenoid valve model suitable for vacuum pressure?

- Q What is the cross sectional area of the wire?

- Q Can the valves be used for hot spring water?

- Q Can terminal boxes attached at site?

- Q Are the parts of DP-100 compatible with DP-10?

- Q Is there valve leakage when the valve is closed?

- Q Can the terminal boxes be rotated?

- Q Can the coil be rotated?

- Q Do the coil's wires have plus side and minus side?

- Q Do motor valves have limitation on flow direction?

- Q In case of power failure, can normally open type solenoid valves be opened manually?

- Q Can motor valves operated manually?

- Q Can solenoid valves operate energized continuously?

QCan thermal insulation cover be put on a solenoid valve?

The coil part should not be insulated.

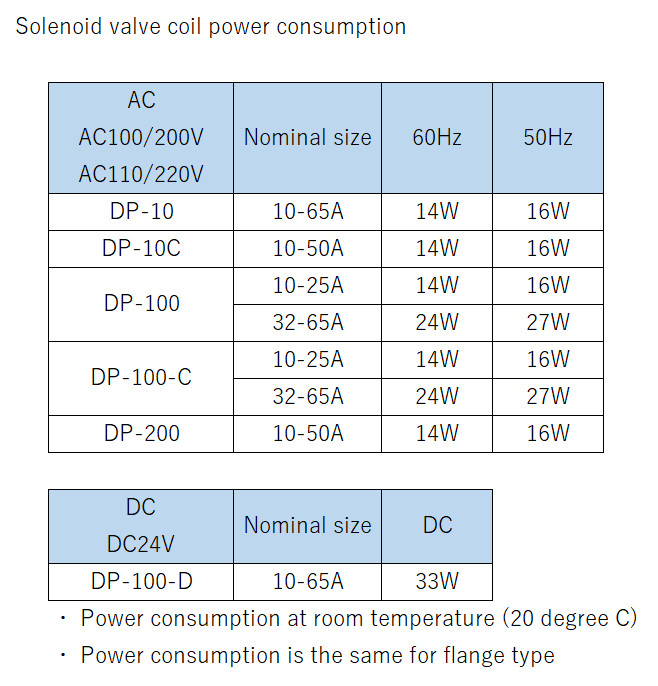

QWhat is the power consumption of the coil of the solenoid valve?

Refer to the catalog of each model.

Solenoid valve coil power consumption table

Solenoid valve coil power consumption table

QHow much water droplet can DP-100 solenoid valve endure?

The coil itself is in degree of protection IP64 (JIS C 0920).

For the terminal box, Model TN-1and TN-2: IP03, Model TN-1C and TN-2C: IP54.

QWhen the power is cut off while being energized, in which state does a motor valve becomes?

When the power is cut off, motor valve stops at intermediate opening.

QWhen the power is cut off while being energized, in which state does a solenoid valve ?

When the power is cut off, normally closed type (NC type) closes and normally open type (NO type) becomes opens.

QAbnormal sound can be heard from the coil of a solenoid valve while being energized. Is it a problem?

No problem. When the product is used with AC voltage, it may produce a buzzing noise depending on the conditions of use.

QHow long is the service life of a solenoid valve?

Although the service life (number of operation cycles) depends on operating condition, model, etc., 100,000 - 500,000 times operation is a standard.

However, DP-100 has recorded 750,000 times operation in in-company tests.

QCan a throttle valve be used at the inlet side of solenoid valves?

Do not use throttle valve and pipes smaller than nominal size of the solenoid valve.

QCan a solenoid valve be used with a three phase power supply?

Our solenoid valve is a single phase 2-wire system.

For a three phase power supply, use two lines, and make sure to insulate the one remaining line.

QCan a solenoid valve be used at a place with explosive gas?

DP-34 with explosion-proof structure can be used.

QThe coil gets hot when solenoid valve is energized. Is it normal?

Yes. The coil rises to about 70 degrees C by being energized.

QIs it possible to use a solenoid valve outdoors?

It is possible. Place protective covers or guards above the product in order to avoid exposure to water.

QWhat is allowable ambient temperature when using a solenoid valve?

No freezing. Use the valve with environmental temperature below 50 degrees C. Do not insulate the coil.

QCan solenoid valves be used for viscous fluids?

Fluid with less than viscosity 20 cSt can be used.

QWhat is the difference between pilot type and direct acting type of solenoid valves?

General differences are as follows;

Pilot type: large flow rate, large product size

Direct acting type: small flow rate, small product size

QAlthough the connection part of DP-100 series is made of stainless steel, is there any problem about galvanic corrosion with a steel pipe? In addition, is there any problem to exchange the solenoid valve made of bronze (DP-10) in use to the one made of stainless steel (DP-100)?

There is no problem.

Since galvanic corrosion influences the surface area ratio of wetted parts greatly, most influences of galvanic corrosion can be disregarded for real piping with larger surface area of steel pipe than stainless steel.

Although we supply the product with stainless steel made connection parts other than DP-100 series, there is no case where galvanic corrosion become a problem until now. In addition, the corrosion potentials of bronze and stainless steel is almost the same. Since there are no difference in condition of galvanic corrosion and no problem with bronze, it can be said that there is also no problem for stainless steel.

QCan a solenoid valve be installed to a place where the piping may be frozen?

No. In case of a possible frozen pipe, keep the valve casing warm or take some other measures to prevent freezing.

However, do not keep the coil warm. If kept warm, the suction power of the coil may be reduced or the coil may be burned.

QAre there any instructions on installation posture of solenoid valves?

Basically, the valve can be installed horizontally or vertically as you desire. However, the vertical installation is limited to the condition that the differential pressure between the inlet and outlet sides is 0.1MPa or more. Besides, we recommend the horizontal installation where possible because the vertical piping tends to cause malfunction in the sliding part due to the scales after a long period of stoppage. In the case of the horizontal piping, the valve must be installed with its coil upward or at least at the horizontal position. Do not install the valve with the coil downward.

QWhat kind of problem is expected when the outlet pressure of a solenoid valve exceeds the inlet pressure?

The valve does not close and backflow occurs. Install a check valve at the outlet side of the valve, or any other measures should be taken in such a way that the outlet pressure is kept not to exceed the inlet pressure.

QWhich size of mesh is recommended for the strainer before solenoid valve for steam to prevent foreign substances?

According to Construction standard specifications (for the construction of machinery and equipment) issued by Public Buildings Association, Japan [the 2004 edition], 80mesh or more. We recommend 80 - 100 mesh.

QWhen installing an ON-OFF valve such as a solenoid valve or a motor valve around the pressure reducing valve, in what distance should they be away from the pressure reducing valve?

When installing a solenoid valve, etc. that opens/closes very quickly, it should be placed before the pressure reducing valve if possible, keeping a proper distance (3m and more is recommended).

QWhat is the maximum allowable temperature of the coil?

180 degrees C (insulation class H).

QCan a solenoid valve be used as an emergency shutdown valve?

No, it cannot.

QAre terminal boxes for solenoid valves available?

QCan the coils for 100/200V be used with 110/220V power?

No, it can cause malfunction or breakdown. Please replace with the one with proper voltage.

QWhat kind of safety devices should be used?

Please use a circuit protector (breaker) and a fuse. Medium-speed type is recommended because high-speed type and instantaneous type may be actuated by the starting current. Select a circuit protector with rated current around 1.5 to 2 times of the rated current of the solenoid valve. The rated current of the fuse should be 1 to 1.5 times of the starting current of the solenoid valve. Please consult manufacturer of the safety devices.

QCan terminal boxes with lamp for rated voltage 100V be used with 110V?

Yes, though the service life of the lamp will be shorter.

QIs there any solenoid valve model suitable for vacuum pressure?

No model is available.

QWhat is the cross sectional area of the wire?

0.75mm2 (cable core).

QCan the valves be used for hot spring water?

They cannot be used because they will be corroded.

QCan terminal boxes attached at site?

Yes, work procedures document is available.

QAre the parts of DP-100 compatible with DP-10?

Not compatible. The valve has to be replaced.

QIs there valve leakage when the valve is closed?

There is allowable leakage.

QCan the terminal boxes be rotated?

No, they cannot.

QCan the coil be rotated?

Yes, the coil can be rotated by loosening hexagonal nut on its top. Please tighten the nut after that.

QDo the coil's wires have plus side and minus side?

There are no plus and minus sides on the wires of both AC and DC coils. Please wire according to the manual.

QDo motor valves have limitation on flow direction?

Some models do. Please refer to the drawings and manuals.

QIn case of power failure, can normally open type solenoid valves be opened manually?

No, they cannot. It is recommended to install a bypass valve.

QCan motor valves operated manually?

Yes, they can. Make sure that the power is off before operating manually.

QCan solenoid valves operate energized continuously?

Yes, but DC coil type is recommended.